Craters and dimples in the application of a polyurethane topcoat can significantly impact the visual appeal and quality of a coated surface. These surface defects, characterized by small depressions or irregularities in the finish, are often a result of various underlying factors such as contamination, improper surface preparation, material incompatibility, or application issues. In the context of a yacht coating project, the presence of craters and dimples can detract from the overall aesthetics and durability of the finish, necessitating a systematic approach to identify, analyze, and rectify these defects. By conducting thorough testing, consulting with experts, and implementing targeted corrective actions, it is possible to mitigate the occurrence of craters and dimples, ensuring a flawless and high-quality polyurethane topcoat application on the yacht’s surface.

Identification of Craters and Dimples

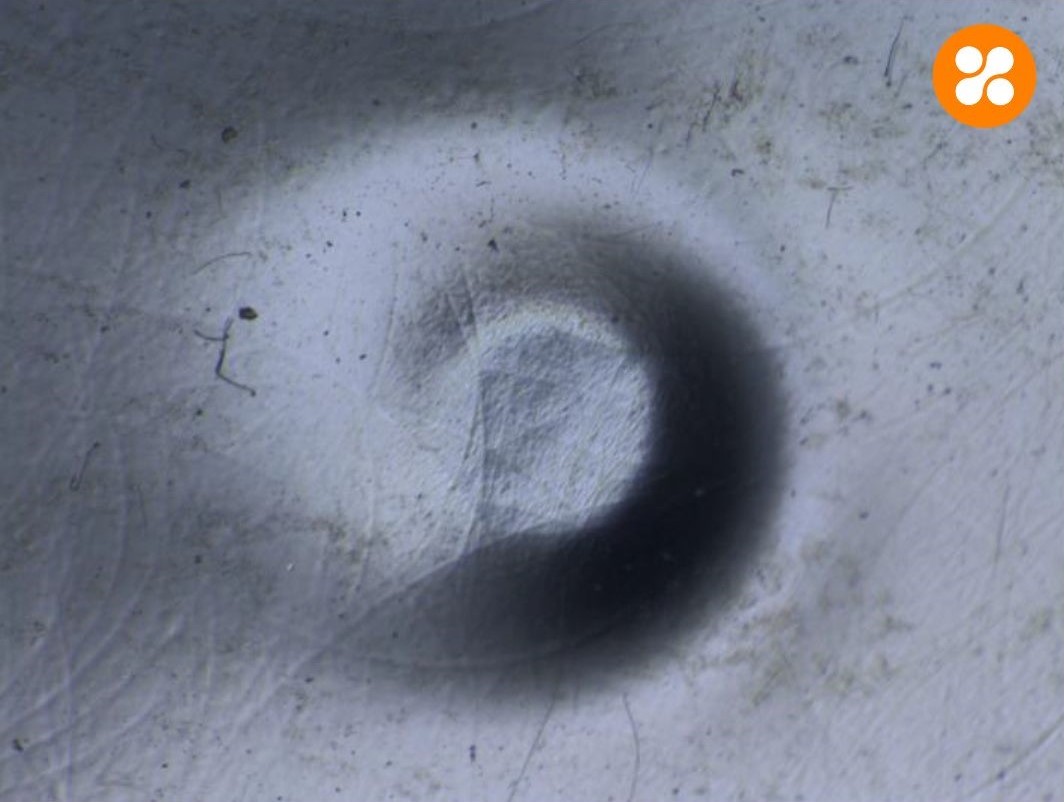

During the quality inspection of a polyurethane topcoat application on a yacht, numerous craters and dimples are observed on the surface, affecting the overall finish and aesthetic appeal of the coating.

Root Cause Analysis:

A thorough investigation is conducted to determine the root causes of the craters and dimples. Factors such as contamination, improper surface preparation, incompatible materials, or application issues are considered as potential causes.

Testing and Analysis:

To pinpoint the specific cause of the surface defects, various tests are conducted:

Contamination Test: Samples from the affected areas are analyzed for the presence of contaminants like silicone, oil, or dust using surface analysis techniques.

Adhesion Test: Adhesion tests are performed to assess the bond strength between the topcoat and the substrate, identifying any adhesion issues that may contribute to the defects.

Consultation with Experts:

Coating technologists and experts in polyurethane applications are consulted to review the test results and provide insights into the specific challenges associated with craters and dimples in the topcoat finishing.

Corrective Actions:

Based on the test findings and expert recommendations, the following corrective actions are implemented:

Improved Surface Preparation: Enhanced cleaning and decontamination procedures are introduced to ensure a clean substrate for the topcoat application.

Material Compatibility Check: Compatibility tests are conducted to verify the suitability of the topcoat with underlying layers and primers to prevent chemical reactions leading to surface defects.

Optimized Application Techniques: Adjustments in spraying pressure, temperature control, and application methods are made to achieve a more uniform and defect-free coating.

Validation and Monitoring:

After implementing corrective actions, the application process is monitored closely, and validation tests are conducted to assess the effectiveness of the improvements in reducing craters and dimples.

Continuous Improvement:

Regular reviews and feedback mechanisms are established to continuously improve the polyurethane topcoat application process, ensuring long-term quality and durability of the yacht’s finish.