Mitigating health risks and ensuring safety in ceramic coating removal: A comprehensive approach.

Thin film ceramic coatings, commonly applied in the Yacht and automotive industry for Gloss restoration, play a vital role in enhancing surface protection and durability. These coatings often contain ceramic compounds like silica, known for their hardness and resistance properties. However, improper removal of ceramic coatings, especially those containing silica, can lead to the presence of crystalline silica particles on the car’s surface, posing health risks due to potential dust exposure.

When considering sanding ceramics to remove a ceramic coating and the associated risk of silicosis due to silica dust exposure, an alternative approach to mitigate the dust particles is to use a removal gel specifically designed to dissolve or soften the ceramic coating. By using a removal gel, the need for sanding or grinding, which can generate airborne dust particles containing crystalline silica, is minimized. This method helps reduce the risk of silica dust exposure during the removal process in yacht and car refinishing.

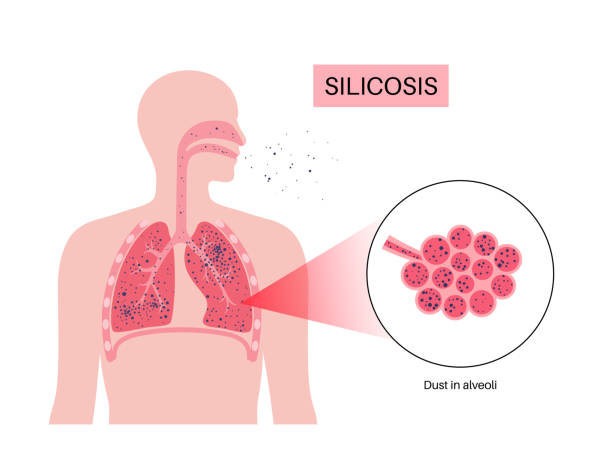

Silicosis is a lung disease caused by inhaling crystalline silica dust over an extended period, leading to inflammation and scarring in the lungs, impairing breathing and lung function.

Application of Removal Gel: Apply the ceramic coating removal gel according to the manufacturer’s instructions. The gel works to break down the ceramic coating, allowing it to be easily removed without the need for sanding or grinding. This approach minimizes the generation of dust particles containing crystalline silica, promoting a safer working environment.

Protective Measures: Even when using a removal gel that reduces dust generation, it is essential to wear appropriate personal protective equipment (PPE) during the removal process. Respiratory protection, gloves, eye protection, and protective clothing should be worn to prevent exposure to any residual dust or vapors.

Ventilation: Adequate ventilation in the work area is crucial to disperse any fumes or vapors emitted during the application and removal of the gel. Proper ventilation helps maintain air quality and reduces the concentration of any chemical vapors, ensuring a safer environment for workers.

Cleanup and Disposal: After softening and removing the ceramic coating with the gel, clean the surface thoroughly to eliminate any residue of the gel and dissolved coating. Wet cleaning methods or a HEPA-filtered vacuum can help minimize remaining particles. Dispose of the removed ceramic coating and any used removal gel following local regulations for hazardous waste disposal to prevent environmental contamination.

By utilizing a removal gel to dissolve the ceramic coating instead of abrasive methods, the risk of generating airborne dust particles containing crystalline silica is significantly reduced, lowering the potential for silica dust exposure and associated health risks like silicosis. Prioritizing safety measures, proper ventilation, and appropriate PPE when using removal gels for ceramic coating removal ensures a safer working environment and minimizes health hazards for individuals involved in the yacht and car refinishing process.

Optimiza has established the CRT method for identifying ceramic compounds on surfaces, prior to the sanding process and coating application, which not only ensures that the surface is free from components that generate differences in surface tension and defects in the coating in a paint refit but also can help ensure that all or the majority crystalline silica compounds have been removed from the surface, thereby significantly reducing the health risk to workers.

«Ceramic coatings are an excellent alternative and complement to topcoat finishing systems. You can confidently apply and remove ceramics as long as you ensure proper removal before sanding and repainting, relying on a professional and experienced team.»