Accelerated ageing tests are essential for assessing the durability and long-term performance of materials used in the construction and maintenance of yachts, boats and other vessels. These tests make it possible to simulate the harsh environmental conditions of vessels at sea, such as continuous exposure to solar radiation, salinity, extreme humidity and temperature changes, all within a short time. This facilitates the prediction of degradation and changes in the properties of marine materials.

This article analyses the methodology of accelerated ageing tests, their importance in the evaluation of composite materials used in boats and their relevance for compliance with regulations and quality standards in the naval industry.

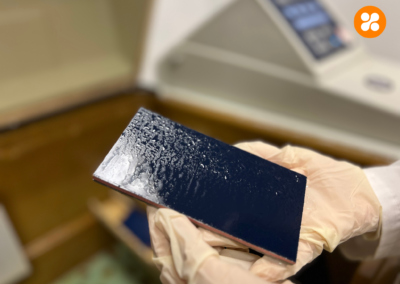

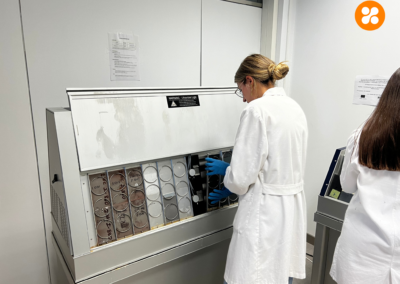

This type of testing is carried out in controlled environmental chambers, where samples of marine materials are exposed to simulated extreme conditions, such as high temperatures, humidity, UV radiation and saline environments. These conditions are selected to accelerate degradation processes and assess the strength and stability of key materials such as fibreglass composites, thermoset polymers and metal alloys, which are essential for the construction and maintenance of yachts and boats.

The results of these tests are crucial for decision making in the design and selection of materials in the marine industry. They enable shipbuilders to meet specific durability, strength and safety standards, ensuring product quality and customer satisfaction. In addition, accelerated ageing tests are essential to demonstrate compliance with international standards such as ISO and ASTM for the durability and performance of materials used in the marine environment.

In conclusion, accelerated ageing tests are a high value-added tool in the marine industry to assess the durability of a wide variety of materials and ensure their long-term performance in extreme marine conditions. By associating these tests with regulations and quality standards, boat manufacturers can demonstrate compliance with regulatory requirements and improve the reliability of their products in the marine market. The combination of accelerated ageing tests and specific regulations drives innovation and the development of stronger, more durable materials for marine applications.